My project is in good condition and most of the parts are present. The biggest work area will be the wing, where the spars exist but there are no ribs. There is also very little left of the wooden fairing strips on the fuselage. Almost all of the sheet metal and fittings are present. Here's some photographs of the project as it was at the previous owner's hangar.

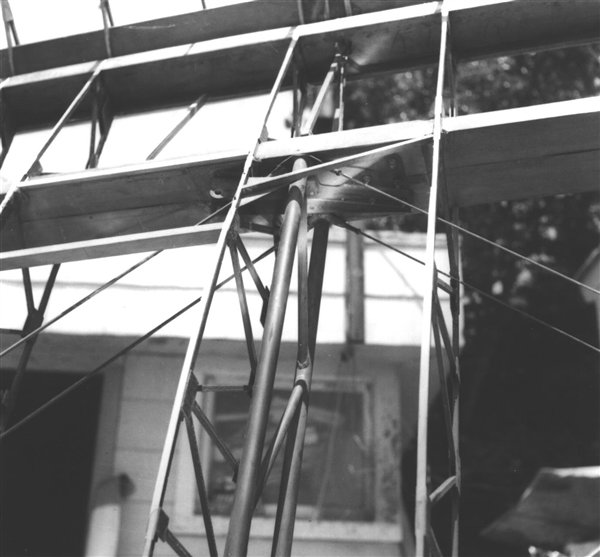

Here's the tubular. It is in remarkably good shape, the main damage being that the turtledeck behind the cockpit was at one point cut off. It has been re-attached with new welds. Note the stub wings welded to the frame. The landing gear oleo mounts on the outer edge of the stub wing. Inside of the stub wing is a baggage locker with doors on the top of the wing. Also note the unique outer wing panel fittings which facilitate wing folding.

Here are the spars. The spars are in ok condition but are somewhat beat up. I will replace them with new wood, using the existing spars as a pattern. The routing work will be tough to duplicate.

This is a detail of the ailerons. The ailerons are nearly full span on the outer wing panel and are Frise-type ailerons. The spar is a built-up box spar made out of thin plywood. The leading edge of aluminum. You can also see the butt ends of the spars in this photo.

The horizontal stabilizer, and elevator, and the rudder. The tail surfaces on this plane are huge.

Miscellaneous parts including a wingtip bow, wing root fairings, the horizontal stabilizer trim jackscrew, and miscellaneous wooden fairings and some rib pieces.

The wing struts, a floorboard, and various covers and sheet metal bits.

The engine. This is a war-surplus B model engine of 125 HP. It will be completely rebuilt before being run.

Here's a few pictures of what the outer wing panels will eventually look like. All of the ribs are built out of wood, and there are steel compression ribs and various fittings such as aileron brackets and strut attach points. The airfoil is a standard Clark Y, and as you can see there isn't any taper except at the outer edges which should save on some jig-building. The leading edge is wooden except for the tip area. The tip bows are wooden.

Compression rib and flying wire detail.

This is a compression rib fitting and aileron bracket (at the top center).